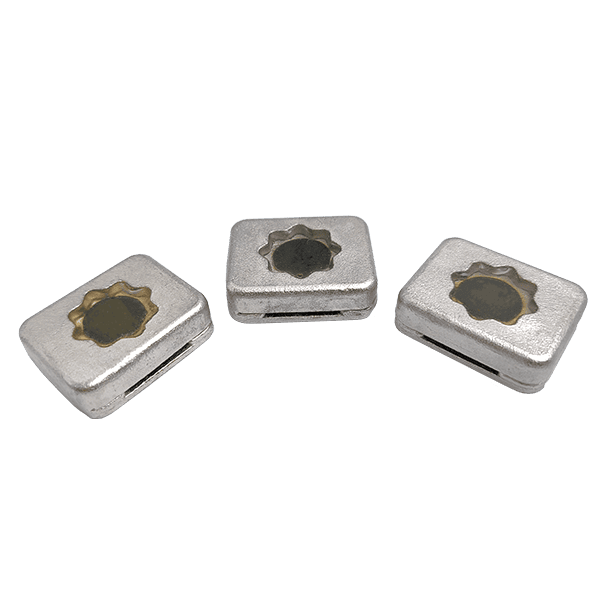

Xerafy PIPETRACKER Cinch is a rugged RFID tag made with premium Material and IP Rating optimized for Oil & Gas Industry, Mining & Construction, Manufacturing

The Xerafy PIPETRACKER Cinch is a rugged RFID tag optimized for tracking pipes and managing industrial assets in harsh environments.

technical description of xerafy PIPETRACKER Cinch

- Material: Made from durable stainless steel 304 and ceramic for long-lasting performance.

- Temperature Resistance: Operates between -40°C to +150°C, with survival capabilities in the same range.

- Pressure and Vibration: Withstands shocks from 3 ft (1 m) drops onto concrete or granite and vibration tested to MIL-STD-810G standards.

- Chemical Resistance: Designed to resist various industrial chemicals, depending on concentration and application environment.

- RF Protocol: EPC global Class 1 Gen 2, ISO 18000-6C, with frequency ranges of 902-928 MHz (US) and 865-868 MHz (EU).

- Memory: Features 96 bits EPC, 48 bits TID, and 688 bits user memory.

- Read Range: Up to 6 ft (1.83 m) with handheld readers.

- Mounting System: Secured using a metal band, with a maximum width of 0.625 inches.

- IP Rating: IP68, ensuring protection against dust and water ingress.

This tag is particularly suited for applications in the oil and gas, mining, construction, and manufacturing industries.

applications of xerafy PIPETRACKER Cinch

The Xerafy PIPETRACKER Cinch RFID tag is designed for industrial asset tracking in harsh environments. Here are its primary applications:

- Oil & Gas Industry: Used for tracking and managing pipes, ensuring efficient operations and maintenance in extreme conditions.

- Mining & Construction: Ideal for monitoring heavy equipment and assets in rugged environments.

- Manufacturing: Suitable for tracking assets in high-pressure and high-temperature industrial processes.

Its robust design, including resistance to chemicals, temperature extremes, and physical shocks, makes it a reliable choice for these demanding industries.

RFID TAG ROSWELL SERIES

The Xerafy TRAK series offers cost-effective inventory RFID tags optimized for identification in the Warehouse, the Factory, the Data Center to deliver real-time visibility into every workflow and lifecycle.

The passive RFID tags for inventory management leverage Xerafy’s field experience with inventory tracking applications and how to meet their requirements and challenges in the field. They offer durability and performance for lower deployment costs and can be combined with the OUTDOOR long range tags and METAL SKIN printable labels series.

“Xerafy is a highly regarded specialist in the field of RFID for mission-critical applications, and their Global Trak RFID tag came out on top of our evaluation.”

How to customize

Standard tagging solutions that are fully personalized for RFID systems, to the exact specifications of the critical assets and equipment they are tracking.

Service Bureau customization options are available to mark and program RFID tags.

On the other hand, RFID labels printing can be done in the field or taken care of by the Service Bureau.

And for unique requirements and features, it is also possible to custom build a tagging solution.

Applicable for tags: Versa TRAK, Data TRAK II, Slim TRAK, Global TRAK

Customized using physical markings to feature an asset identification number, a barcode, or a logo for instance.

Custom asset tags can be custom marked in the field, or be taken care of by the Service Bureau of the manufacturer or distributor.

encode

Programmable tags use RFID chips that are specifically designed with memory that can be written.

This allows for the tags to be encoded with custom EPC ranges for unique identification, serialized or unserialized.

The quantity of information that can be encoded will depend on the specifications of the chip being used.

RFID Engineering

Can be designed specifically for a tracking system’s application and deployment requirements: Form factor, material, mounting system, read range, accuracy, user memory, fixed and/or handheld RFID readers, on-site printers and encoders, software configuration.

Connected assets are an example of custom-built RFID tagging solutions that refer specifically to equipment that OEMs have designed with RFID and IOT features built-in.

If you need more details about this specific subject, MAIL TO

SELECT THE PRODUCT OF YOUR INTEREST (sib)