XERAFY MICRO Heat TAG RFID Designed for High-Temperature Applications: Aerospace & Automotive, Electronics & Semiconductor Cooling, Medical & Bioengineering, Energy & Power Systems

The First Choice for High-Temp

TThe MICRO Heat technology refers to micro heat pipes and micro heat spreaders, which are used for thermal management in electronic devices, aerospace applications, and medical equipment.

technical description of MICRO Heat

- Heat Transfer Mechanism: Operates on a closed two-phase cycle, where heat added to the evaporator region causes the working fluid to vaporize and move to the condenser, where it releases heat and condenses.

- Capillary Action: Uses wicking structures to pump liquid back to the evaporator, ensuring continuous heat dissipation.

- Material Composition: Typically made from copper, aluminum, or silicon-based materials for efficient thermal conductivity.

- Size & Design: Micro heat pipes range from 1 mm to 30 mm in diameter, making them suitable for compact electronic devices.

- Applications: Used in semiconductor cooling, laser diode heat dissipation, photovoltaic cell thermal control, and hypersonic aircraft thermal management.

For more details, you can check out this technical paper on micro heat pipes and their applications.

applications of MICRO Heat

The MICRO Heat technology, particularly microchannel heat exchangers and micro heat pipes, has diverse applications across various industries. Here are some key areas where it is used:

- Aerospace & Automotive: Microchannel heat exchangers are employed in cooling systems for aircraft engines, spacecraft thermal control, and automotive radiators.

- Electronics & Semiconductor Cooling: Used in high-performance computer chips, laser diodes, and power electronics to manage heat dissipation efficiently.

- Medical & Bioengineering: Supports cryosurgery, thermal control in medical devices, and cooling of infrared detectors.

- Energy & Power Systems: Applied in solar power systems, nuclear fusion reactors, and hydrogen storage to enhance thermal management.

- Industrial & Refrigeration: Microchannel heat exchangers improve cooling efficiency in refrigeration and air conditioning systems.

High Temperature RFID Tags That Stand Out

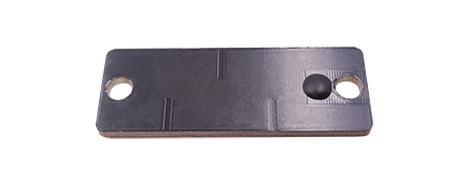

The MICRO series from Xerafy offers the ultimate on metal high temperature RFID tags, providing consistent performance where reliability and durability are critical.

As Xerafy’s leading rugged RFID tags engineered for high temperature on metal tracking, the MICRO series offers durable and reusable tagging alternatives to barcode labels, making them suitable for a wide range of industrial assets.

The waterproof tags use a combination of packaging and casing materials to protect the RFID chip from heat, shocks, corrosion, pressure, and water.

What are UHF RFID tags?

UHF RFID (Ultra High Frequency Radio-Frequency Identification) tags are a type of RFID technology that operates at RFID frequencies between 300 MHz and 3 GHz.

The tags consist of a small antenna and a microchip that stores data about the object being tagged. When the tag is within range of an RFID reader, the reader sends a signal to the tag, which responds with its unique identification number and any other data programmed into the chip.

This information can then be used to track and manage the tagged object.

Unlike barcodes, UHF RFID allows for reading and writing data in bulk, in seconds, from a distance, and out of sight, thus enabling automated asset tracking.

If you need more details about this specific subject, MAIL TO

SELECT THE PRODUCT OF YOUR INTEREST (sib)